Detail Information

Perforated Galvanized Grip Strut Grating Stair Treads Non Slip Metal Sheet

Galvanized Grip Strut Stair Treads Non-slip Metal Sheet Factory

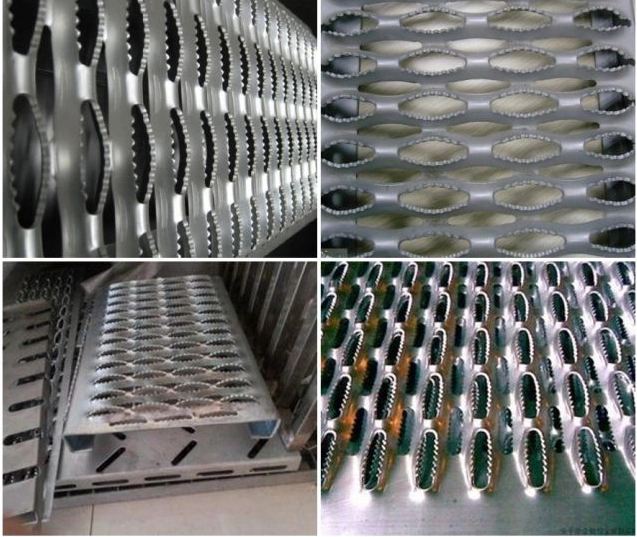

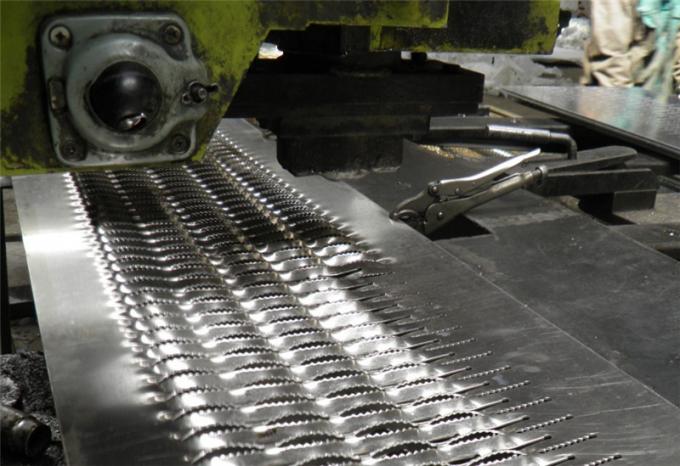

Grip strut stair treads are manufactured as one-piece constructed channels with walking surfaces consisting

of serrated edges on top of diamond shaped openings. The serrated surface is designed in an open

diamond pattern. This allows drainage of fluids, mud, chips and other accident-causing debris.

Grip strut stair treads can be cut or bending to any size and are ideal for wet or dry conditions where good slip resistance

and traction are needed, adapt to different ground and anti-skid requirement.

1. Grip Strut Stair Treads Specs

-

Materials: Mild steel, Galvanized Steel, Stainless steel, Aluminum

-

Surface treatment: Galvanized, Original, Painting and Powder coating

-

Thickness of materials : 1.5-3.5mm

-

Opening size : Standard or customized

-

Opening shape : Round,Diamond or customized.

|

Material

|

hot rolled, cold rolled, aluminum, galvanized plate,

stainless steel panel etc.

|

|

Width

|

4-3/4", 7", 9-1/2", 11-3/4", 18-3/4" and 24".

|

|

Thickness

|

1-5mm

|

|

Channel height

|

1-1/2”, 2”, 2-1/2” and 3”.

|

|

Characteristics

|

anti rust and anti-corrosion,characteristics and the rugged appearance.

|

|

Use

|

Anti-skid plate can be widely used in sewage treatment, power plant,

snow, stair step, antiskid pedal, and many other anti-skid areas.

|

2. Grip Strut Stair Treads Features

Grip Strut Stair Treads are available in a variety of hole shapes,thicknesses and surface treatment according

to the applications and loading requirements.

Economical to install, use

In addition to low material cost and nominal erection cost, Grip Strut Safety Grating also saves with its long-lasting,

rustresisting materials and finishes. Standard mill-galvanized finish resists corrosion to provide lasting surfaces.

High-strength aluminum and Types 304 and 316L stainless steel are available to provide maximum corrosion resistance.

Black unpainted steel available for installations requiring hot dipped galvanized finish after fabrication. These light weight

but brawny panels permit substantial reduction in structural steel requirements. Open design is self-cleaning and virtually

maintenance free.

Safer, serrated surface

Grips soles securely - in all directions - in practically every place. These non-slip Grip Strut Grating surfaces are ideal for

inside or outside locations where mud, ice, snow, oil and detergents can create hazardous walking conditions. Openings

are small enough to catch most falling tools and other dangerous objects.

Maintenance-free open

design Permits quick drainage of fluids, chips, grease and mud. Any ice accumulation shears easily under normal foot

pressure. Open design allows convenient access for cleaning. It is easily cleaned with brush, liquid or air spray to minimize

overall maintenance.

High load capacity, long life

High strength-to-weight performance is achieved through depth of section and structural design. Bridged struts with integral

side channels form a plank that can support loads with minimum transverse and longitudinal deflection. There are no rivets or

pressure joints to break or loosen. This sturdy construction provides the advantages of heavy load-carrying capacity with

minimal deflection; rugged durability with longerlasting performance.

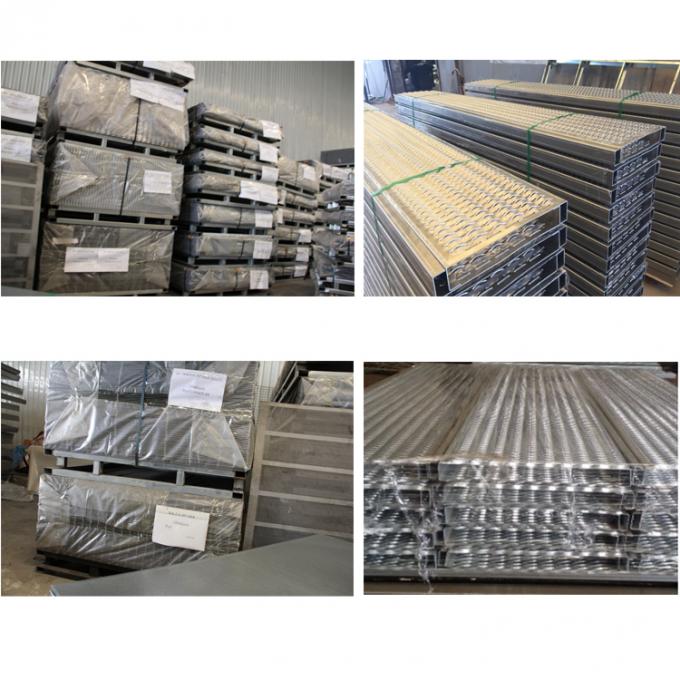

Fast Installation

Light, easy-to-handle planks make installation simpler and quicker. They can be handled by one man. Most sections are

rapidly bolted, clamped or welded into place, easily field-cut at virtually any angle, or fabricated to adapt to field conditions.

Several attachment devices permit fastening to most existing surfaces; allow fast installation or disassembly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!