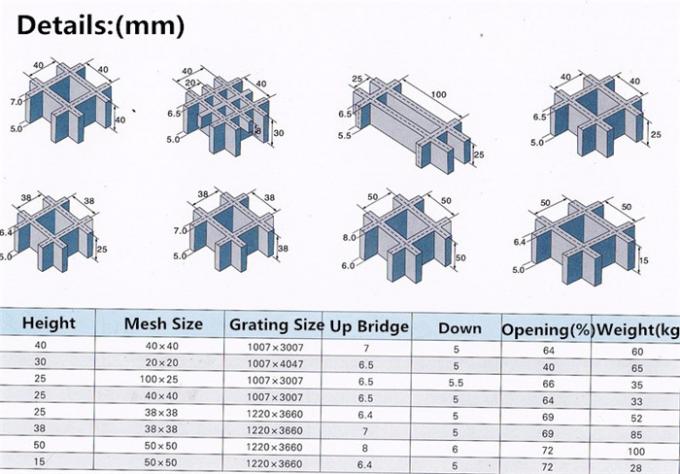

Detail Information

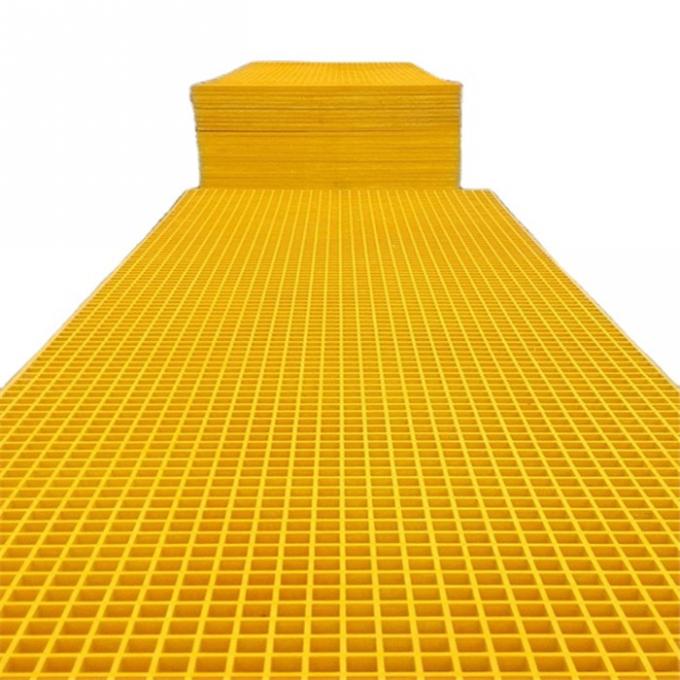

Fire Resistance Solar Panel Rail Walkway Fiberglass Grating

Yellow Fiberglass Grating Walkway For Solar Panel Rail

Brief Introduction of FRP grating

Fiberglass Reinforced Plastic (FRP) is a plank shaped material cured in the matrix of unsaturated resins including

isophthalic, orthophthalic, vinyl ester and phenolic, with reinforced frame of fiberglass roving through a special

production process, with a certain rate of open meshes.

FRP Molded Grating is a structual panel which uses high-strength E-Glass roving as reinforcing material,thermosetting

resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight,high strength,

corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering,

water & waste water treatment,ocean survey as working floor, stair tread,trench cover,etc,and is an ideal loading frame

for corrosion circumstances. Our product passes a whole series of well known third party tests with the fire and mechanical

properties,and the product sells well all over the word and has a good reputation.

FRP plastic grating is available in a variety of resins, standard and custom colors, depths, panel sizes and mesh

configurations. Surface options include a meniscus or integrally applied git top, both of which offer superior, slip resistant

footing. FRP molded grating is used in place of traditional materials for a FRP solution that fits a wide range of applications

and environments.

1. Pultrded Profile Steel Bar Grating/Frp Grating

Fiberglass floor floor Grating is available in a variety of resins, standard and custom colors, depths, panel sizes and mesh

configurations, it is used for their high strength, corrosion resistance, light weight, long life and safety. All FRP grating is made

to meet the highest international standards.

FRP molded grating surface options include a meniscus or integrally applied grit top, both of which offer superior, slip resistant

footing. also has many advantages over steel grating for performance and cost effectiveness. With a much higher strength-to-weight

ratio, molded fiberglass grating is easy to handle, making for quick installation.

Molded grating is manufactured in an open, heated mold that resembles a large waffle iron. Continuous glass fibers are placed in the

mold in alternating layers and thoroughly wetted out with resin. This continuous process produces an integral, one-piece construction,

which offers excellent corrosion resistance as well as bi-directional strength. the weaving process is completed, the mold is heated to

cure the panel. If the grating is to have embedded grit, the mold will receive the grit at this time before the part is cured. After curing,

the part is extracted from the mold. The standard part would have a meniscus (concave) top surface for slip resistance. Should a

standard grit surface be specified, the grit would be bonded to the top of the completed grating panel as a secondary operation.

2. Fiberglass plastic floor grating specification

|

Material

|

Phthalic resin or iso-phthalic resin

|

|

Processing technology

|

Molded

|

|

Surface treatment

|

Flat, concave, grit cover, checkered plate

|

|

Color

|

Any international standard color

|

|

Fixing clips

|

SS316 material: C/L/M types

|

3. Fiberglass plastic floor grating advantages:

Corrosion Resistant

Bi-directional Strength

Slip Resistant

Low Maintenance

High Strength to Weight Ratio

Fire Retardant

Lightweight

Impact Resistant

Long Service Life

Superior Ergonomics

4. Fiberglass plastic floor grating applications:

chemical processing

marine

oil & gas

power

manufacturing

construction

metals & mining

recreation

water parks

telecommunications

shipping centers

transportation facilities

water & waste treatment, and

numerous architectural uses.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!